Custom rolling trays aren’t just handy tools—they can actually be game-changers for your brand. When done right, they go from being everyday items to something your customers actually connect with. With a smart design and production plan, you can turn a simple tray into a statement piece. This guide breaks it all down for you: how to create, brand, and grow your line of custom rolling trays in a way that really fits your business.

Before you dive into designing your custom rolling tray, hit pause for a sec. Step back. What’s the bigger picture here?

Are you making these to sell in stores? Toss into promo packs? Maybe bundle up with other gear? Figuring that out upfront saves you a ton of backtracking later. Seriously—knowing your why makes every other decision way easier.

Then think about who you’re actually designing for. Are your people into clean, minimal looks—or wild, colorful art that jumps off the tray? The better you know their style, the more likely you’ll create something they’ll be proud to use—and show off.

Now for the not-so-fun-but-super-important part: budget. What can you actually spend? What price makes sense? How does this tray fit in with everything else you sell? Thinking about stuff like margins and product lineup now helps avoid “uh-oh” moments later.

Some brands go all in and create full-on themed sets, trays, jars, lighters, all matching. It doesn’t just look cool, it makes your brand feel more polished. Plus, it gives customers a full experience, not just a one-off item.

Oh—and definitely take a look at what other brands are doing. Doesn’t mean you copy ‘em, but it helps you figure out how to do something different, something that really stands out.

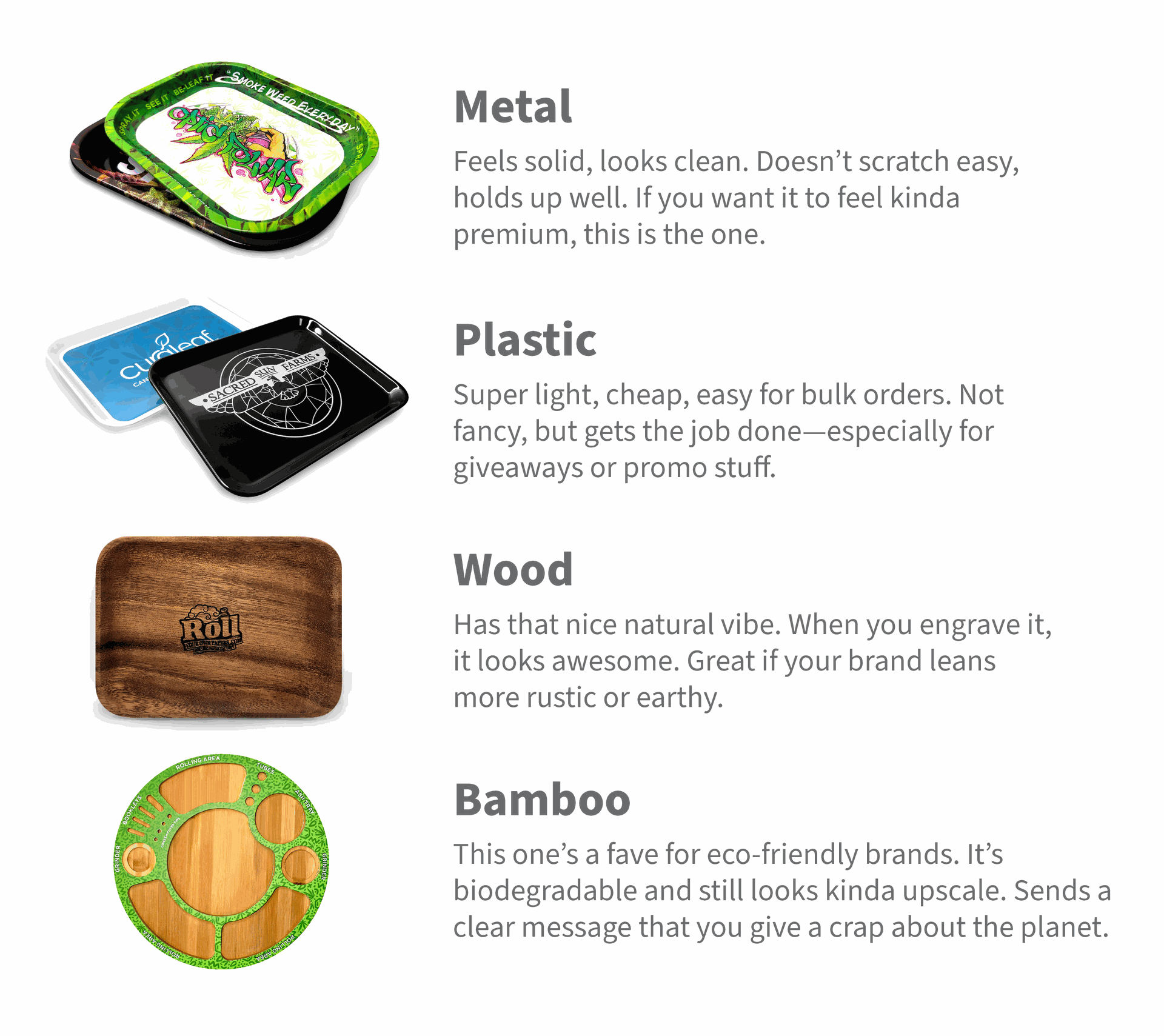

Alright, real simple—what your tray’s made of actually matters. Like, a lot. It affects how it looks, how it feels, how long it lasts, and how much it’s gonna cost you to produce. So yeah, don’t just pick the first thing that sounds cool.

Here’s the lowdown:

- Metal – Feels solid, looks clean. Doesn’t scratch easy, holds up well. If you want it to feel kinda premium, this is the one.

- Plastic – Super light, cheap, easy for bulk orders. Not fancy, but gets the job done—especially for giveaways or promo stuff.

- Wood – Has that nice natural vibe. When you engrave it, it looks awesome. Great if your brand leans more rustic or earthy.

- Bamboo – This one’s a fave for eco-friendly brands. It’s biodegradable and still looks kinda upscale. Sends a clear message that you give a crap about the planet.

Each one comes with different finish options—gloss, matte, UV, whatever. Just think about what you’re trying to say with the tray and what your people actually care about.

End of the day, this tray isn’t just for rolling—it’s part of your brand. So don’t half-ass it.

This is the part where your custom rolling tray manufacturing stops being basic—and starts being something people actually remember.

Kick things off with a clean, high-res template from a solid manufacturer (SmokGear’s a good bet). Then crack open Illustrator, Photoshop—whatever you like—and start making it yours.

Use colors that really fit your brand’s vibe, and double-check that your logo’s in vector format. That way, it looks sharp whether it’s the size of a dime or stretched across the whole tray.

Want to take it up a notch? Add something personal. Maybe a nod to your neighborhood or a piece from a local artist. Featuring commissioned art isn’t just cool—it gives your tray some real soul and tells people who you are without saying a word.

And hey—don’t forget functionality. Looks are great, but how the tray works matters, too. Some come with grooves, magnetic spots, or tool holders. If you’re going all-in and designing a set, think about extras like measurement lines or accessory slots. Basically, it should look awesome and make life easier for your customer.

Once your design is approved, it's time for production. This step varies based on material and scale:

- Metal trays: Often use sublimation or screen printing and go through cutting, forming, coating stages.

- Plastic trays: Typically injection molded and then pad-printed or UV printed.

- Wood or bamboo trays: Require CNC routing and laser etching or heat transfers.

Always ask for a sample or prototype before confirming a large order. Quality control is key to ensuring every piece that leaves the factory represents your brand well. Manufacturers like SmokGear often allow for low MOQ prototyping, which is perfect for testing market reactions before going all in.

The final look of your tray depends on both design and finish. Here are a few options:

- Glossy or matte finish: Affects how colors appear — gloss is vibrant, matte is subtle.

- Foil stamping: Adds metallic or holographic elements to logos.

- UV Spot Coating: Makes certain design elements pop visually and tactically.

- Embossing/Debossing: Adds texture for a more premium feel.

Consider pairing your trays with branded boxes, sleeves, or even eco-pouches. A fully branded unboxing experience enhances perception and increases shareability on social media. Even limited editions or artist collaborations can make your trays collectible items.

Once you’re happy with how your custom rolling trays turned out it’s time to think about scaling up. This is where things start to get real. Most manufacturers give discounts if you order more—so yeah, bigger orders = lower cost per tray. But before you hit that big “buy” button, let’s go over the stuff you don’t want to overlook.

- MOQ (Minimum Order Quantity) – This one varies a lot. Some places let you do small runs, others want a few hundred minimum. You just gotta ask. Don’t assume anything.

- Lead times – These aren’t always quick. Depending on the material and how custom your design is, production might take anywhere from 2 to 6 weeks. So yeah—don’t leave this for the last minute or you’ll be stuck waiting.

- Shipping & customs – If you’re getting these made overseas, give yourself extra time and budget. Shipping costs can sneak up on you, and import fees? Those can be brutal if you didn’t plan for ‘em.

- Distribution – Alright, how are you actually getting these trays to people? Selling online? In stores? Wholesaling to other businesses? Maybe you’re using them for brand gifts or kits. There’s no single right way—just depends on what fits your brand and how much time you want to spend dealing with orders.

And if the idea of packing and shipping rolling trays one by one sounds like a nightmare (which, let’s be honest, it kind of is), you can always work with a partner like SmokGear to handle fulfillment for you. Let them deal with the headaches.